Save Energy & Labor

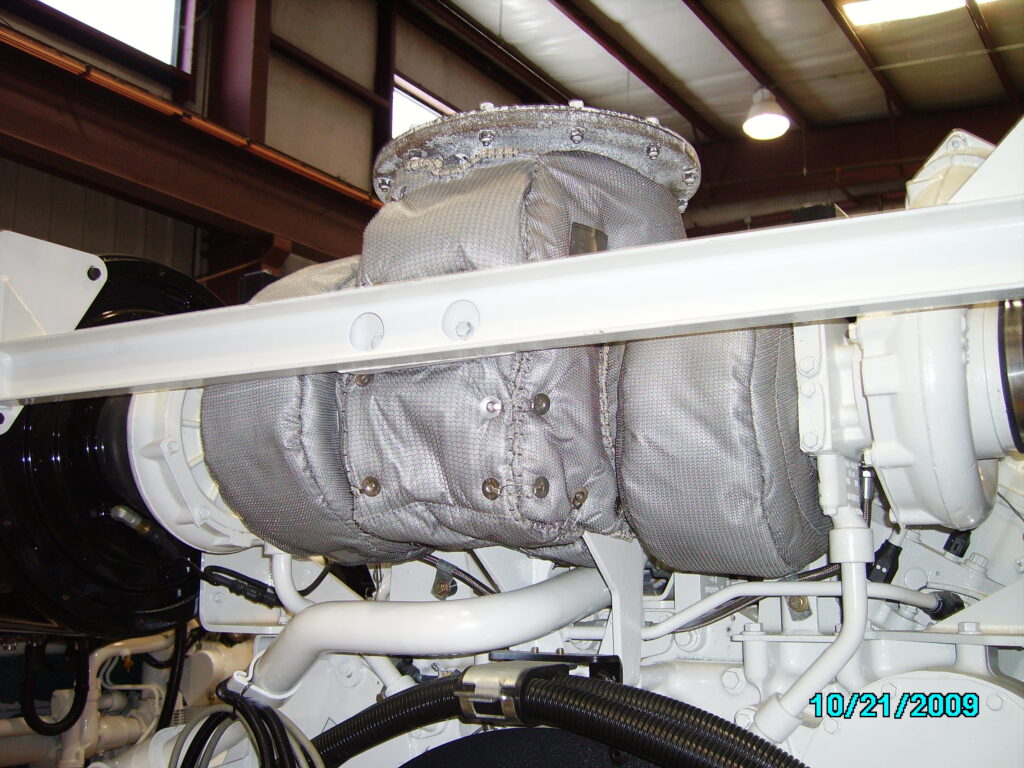

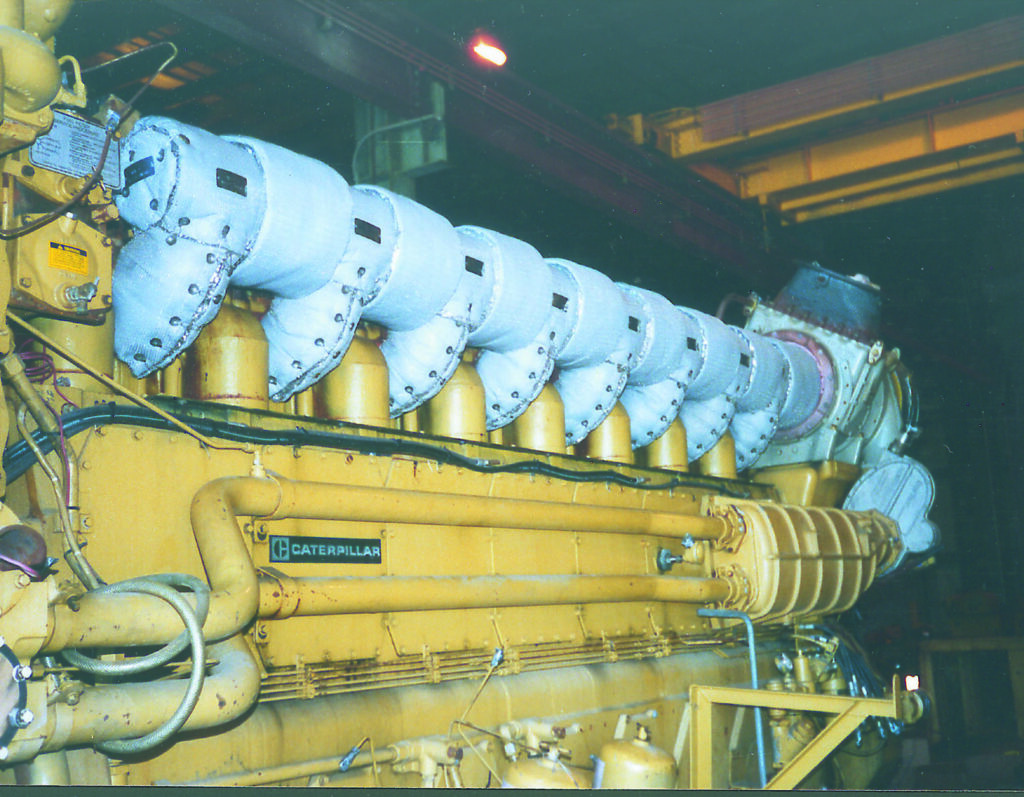

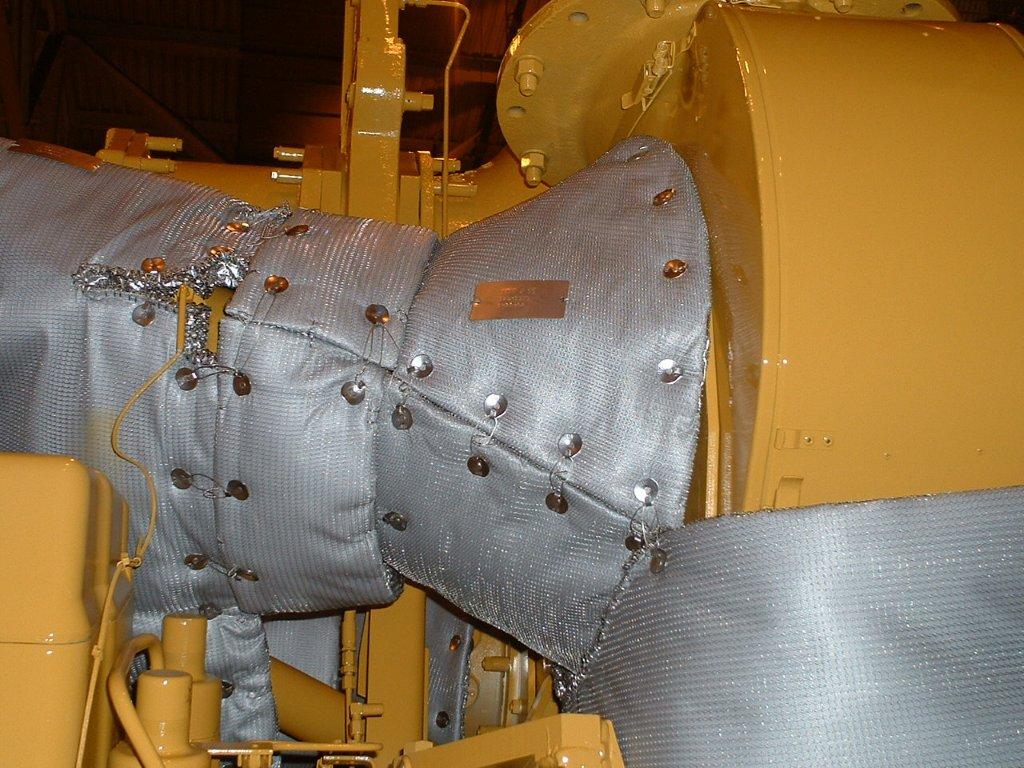

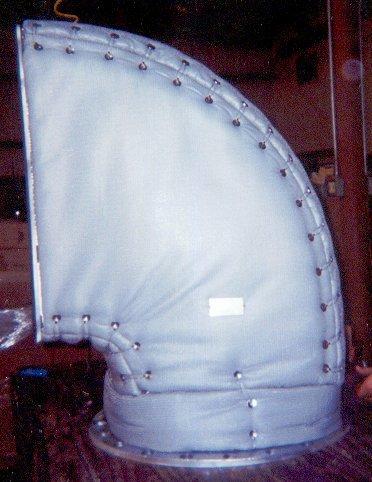

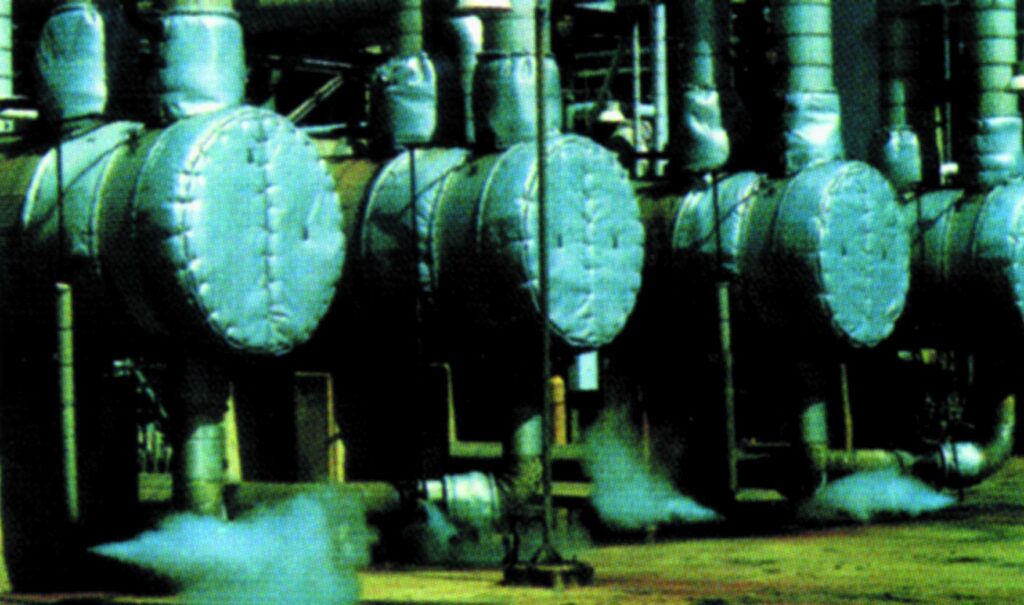

Constructed for any temperature or atmospheric environment, Temp-Set® Covers can usually be installed while process is on line. They are very durable, weather resistant and ideally suited for any area that requires frequent maintenance. Standard applications include heat exchangers, valves, manways, flanges, pumps, engine manifolds, engine exhausts, exhaust silencers and turbines. All covers are custom designed and guaranteed to fit closely to minimize heat loss.

Built To Your Specs

Our trained representatives are available to assist you in developing insulation specifications to meet your requirements. Temp-Set® Covers can be manufactured using either a hog-ring staple manufacturing assembly or a sewn assembly, both with a variation of seaming capabilities.

Specification Categories

- 150-450°F Interior 1

- 150-450°F Exterior 2

- 150-450°F Haz. Envir. 3

- 450-1200°F interior 1

- 450-1200°F Exterior 2

- 450-1200°F Haz. Envir. 3

- 1200-2300°F Interior 1

- 1200-2300°F Exterior 2

- 1200-2300°F Haz. Envir. 3

1 Interior – not exposed to weather.

2 Exterior – exposed to weather.

3 Haz. Envir. – caustic or acidic appl..

Highest-Quality Construction

A needled glass fiber core is central to the Temp-Set® Covers, this is ordinarily used for temperatures up to 1200° F. A ceramic fiber insulation is available for temperatures up to 2300° F. The thickness of the fiber core can vary from one to four inches, depending on the application.

A siliconized glass fiber is normally used for the covering of the fiber core. It is impervious to fuel and water. Stainless steel foil, *Hypalon®, *Teflon® (*Registered trademark of I.E. Dupont De Nemours) and other covering materials are available.

To reduce noise, barriers such as lead loaded or reinforced vinyl can be added for improved acoustical applications. The total composite is encapsulated in 304 stainless steel mesh (monel and inconel are also available). All accessories, such as lacing hooks and staples, are available in these materials. Then Temp-Set® Covers are tagged with stainless steel embossed tags in order to offset any delays caused by misplaced blankets and aid in installations.